Anchors in masonry structures are commonly used to attach different structural and nonstructural masonry components. Types, installation, anchorage length and its strength is discussed.

The structural members which required anchors to be attached to masonry involves ledger beam, girders, floor and roof diaphragms, and other members that possibly need to transfer their load to the masonry.

An example of anchoring utilization in masonry structures is Floor and roof diaphragms which are usually carried by girder and loads from girders are transferred to masonry through anchoring girder to masonry.

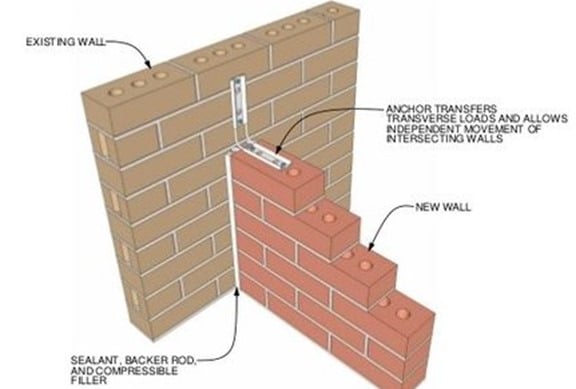

Not only do anchors transfer gravity loads to masonry but they also can transfer lateral loads as well. Building Code Requirements and Specifications for Masonry structures (ACI 530.1-11) provide requirements and design methods for masonry anchorage.

In this article, different aspects of anchors in masonry structures are discussed in the following sections.

Fig.1: Anchoring of New Masonry Wall to Existing Masonry Wall to Transfer Lateral Loads

Anchors in Masonry Structures – Types, Installation, And Anchorage Strength

- Types of anchor bolts used in masonry

- Installation of anchor bolts in masonry grout

- Factors affecting the strength of anchor bolts

Types of Anchor Bolts Used in Masonry Structures

There are different kinds of anchor bolts which are used in the construction of masonry structures and these anchor bolts are categorized as follows:

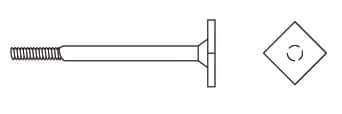

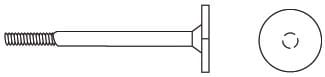

Plate anchor bolts that possess round or square plate at the end which is not threaded as shown in Figure-2 and Figure-3.

Fig.2: Square Plate Anchor Bolts for Masonry Structures

Fig.3: Round Plate Anchor Bolts for Masonry Structures

Bent bar anchor bolts which their shapes similar to letter L and letter J as it can be seen from Figure-4 and Figure-5.

Fig.4: L-Shaped Bent Bar Anchor Bolt for Masonry Structures

Fig.5: J- Shaped Bent Bar Anchor Bolt for Masonry Structures

Headed anchor both with square or hexagonal head, Figure 6 and Figure 7.

Fig.6: Square Head Anchor Bolt for Masonry Structures

Fig.7: Hexagonal Headed Anchor Bolt for Masonry Structures

Installation of Anchor Bolts in Masonry Grout

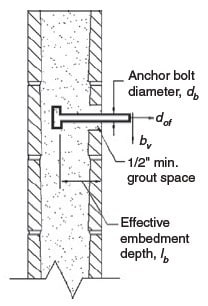

Both grout thickness encircled bolts and length in the grout are substantially influential on the strength of bolt anchor. Loads of components anchored to masonry are transferred through grouts around the bolt, so adequate amount of grout should be provided to obtain successful anchorage.

ACI 530.1-11 provides specifications related to the installation and embedment of anchor bolts in grouts.

The ACI 530.1-11 recommends that, the embedded anchor bolts need to be grouted with minimum grout thickness of 12.7mm between masonry and anchor bolts disregard of the type of the bolts which is being used.

This specification may not be followed and thickness of the gout can be decreased if the diameter of the anchor bolt used is 6.35mm. it is worth mentioning that, exception is not common in practical world.

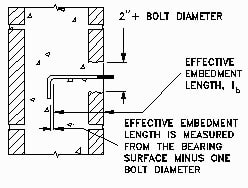

The anchorage strength for all kinds of bolts is based on effective embedment length which is denoted as (lb), and the effective embedment length for each bolt type is not the same.

Effective embedment length for bent bar anchor bolts is the perpendicular distance from masonry surface to the compression bearing surface of bent end minus one bolts diameter, and effective embedment length for headed anchor bolt is measured from masonry surface perpendicular to the compression bearing surface of the anchor bolt head.

Effective embedment length for both headed anchor bent bar anchor bolt and headed anchor bolts are illustrated in Figure-8 and Figure-9 respectively.

Fig.8: Effective Embedment Length of Bent Bar Anchorage

Fig.9: Effective Embedment Length for Headed Anchor Bolts

The ACI 530.1-11 states that, the minimum effective embedment length need to be greater than 50.8mm or four times the diameter of the bolt disregard of the type of anchor bolt and type of the load which includes shear, axial tension, or combined axial tension and shear.

The minimum effective embedment length is specified depend on the method by which anchor bolts are installed in the grouts of masonry.

Factors Affecting Strength of Anchor Bolt in Masonry Structures

There are several factors that influence the anchor bolt strength used in masonry structure and these factors are stated below:

- The type of the load applied; it may be tension, or shear, or combined tension and shear

- Failure modes

- Type of anchor used to provide anchorage in masonry structure

- Masonry compressive strength

- Effective embedment length of the bolt employed

- Diameter of used anchor bolt

- Yield strength of utilized anchor bolt

- Projected extension of bent bar anchor bolts

- Condition of the anchor bolt

Please give some advice on how to achieve this kind of posts. Rectify

ReplyDeleteThanks for sharing this informative post. When I read your post I understood the correct use of different types of fasteners. If anyone is looking for high-quality A4-70 Stainless Steel Hex Nut, you can visit this official site Vision Alloys.

ReplyDeleteAuthentic platform to find the leading nut bolt industry here. Deal with Sumit Impex for Quality UNS S31000 Fasteners at true cost.

ReplyDeleteI'm really impressed with the details you give. This is an interesting article for me as well as others. Thanks for sharing such articles here. UNS N08904 Seamless Pipe.

ReplyDeleteYour post was so well written and easy to understand Thank you for breaking down [topic] in a way that anyone can understand.

ReplyDeleteUNS S32750 Erw Pipes

Thank you for sharing your personal experiences with [topic] It's always helpful to learn from someone who has been there.Bare Copper Conductor

ReplyDeleteThis post was so inspiring! You reminded me why this is so important.

ReplyDeleteHastelloy C22 Bolt

Your analysis was very informative. It's clear that this is an issue that requires more attention in the industrial sector.

ReplyDeleteASTM A240 SS 304L Shim

Your insights were very helpful. I appreciated the way you broke down this complex issue into more manageable parts.

ReplyDeleteUNS S31803 Sheets

Your writing made me pause and contemplate a number of points. Clearly, you have extensive knowledge of the challenges presented by the manufacturing industry. Deal with the S355J2+N Pipes Stockist for high-Quality EN 10210 S355J2 N Pipe at a fair price.

ReplyDeleteI liked how clear and accurate your post was. I needed that explanation to keep up. This page showed me the best way to do something. If you want to find out more about plates, you should look at EN 10025-6 Weldox 700 Plates.

ReplyDeleteI value the extensiveness of your explanation. I know I'm not alone in thinking this is an interesting read. Check out my site if you want to know more about 316 stainless steel round bar.

ReplyDeleteI appreciate your detailed explanation. Your writing made me rethink. You clearly know industry. Visit my site for Duplex S32205 Pipe information.

ReplyDeleteYour article was very interesting to us. It's clear that you've done extensive research into the manufacturing industry. Come see us if you need Tongue & Groove Flanges .

ReplyDelete